Why do home appliances need to be prototyped before mass

production?

Home appliances need to be prototyped before mass production for

several important reasons:

Design Validation: Prototyping allows designers and engineers to

validate and refine the appliance's design. It provides an

opportunity to assess the functionality, ergonomics, aesthetics,

and overall user experience of the product. By creating physical

prototypes, designers can identify design flaws, make necessary

improvements, and ensure that the appliance meets the intended

design objectives.

Performance Testing: Prototyping facilitates comprehensive

performance testing of an appliance. It involves assessing its

functionality, durability, safety features, energy efficiency, and

adherence to industry standards and regulations. Testing prototypes

is crucial for detecting potential problems, such as mechanical

failures, electrical malfunctions, or subpar performance, and

enables the implementation of required modifications prior to mass

production.

Ergonomics and User Experience: Prototyping allows for the

evaluation of the appliance's ergonomics and user experience. It

provides an opportunity to assess factors such as ease of use,

button placement, control interfaces, accessibility, and overall

comfort. Feedback from users interacting with prototypes can help

optimize the design to ensure a positive and intuitive user

experience.

Cost Optimization: Prototyping enables the identification of

cost-saving opportunities within the manufacturing process. It

allows engineers to test the viability of production techniques,

assess material options, and pinpoint where costs can be trimmed

without sacrificing the functionality or quality of the appliance.

Marketing and Stakeholder Feedback: Prototypes serve as crucial

tools for marketing and collecting stakeholder feedback. They are

instrumental in product demonstrations, presentations, and focus

groups, highlighting the appliance's features, design, and

functionality. Gathering input from prospective customers,

retailers, and investors is essential for making informed decisions

and refining the product prior to mass production.

Tooling and Manufacturing Preparation: Prototyping helps in

preparing for mass production by providing insights for tooling and

manufacturing processes. Prototypes can be used to develop

production tooling, assess assembly methods, optimize production

workflows, and estimate production costs. This helps ensure a

smooth transition from prototyping to mass production, minimizing

potential issues and reducing costly revisions during the

manufacturing phase.

By prototyping home appliances before mass production,

manufacturers can mitigate risks, improve product quality, enhance

user satisfaction, optimize production processes, and increase the

likelihood of a successful market launch. It allows for thorough

evaluation and refinement of the appliance's design, performance,

and user experience, ultimately leading to a better final product.

Assembly and Functional Integration: Assemble the painted

components, ensuring that they fit together accurately and function

as intended. This includes integrating electrical components,

control panels, doors, handles, and other relevant parts. The

functionality of the prototype should closely resemble that of the

final product to facilitate in-home testing and evaluation.

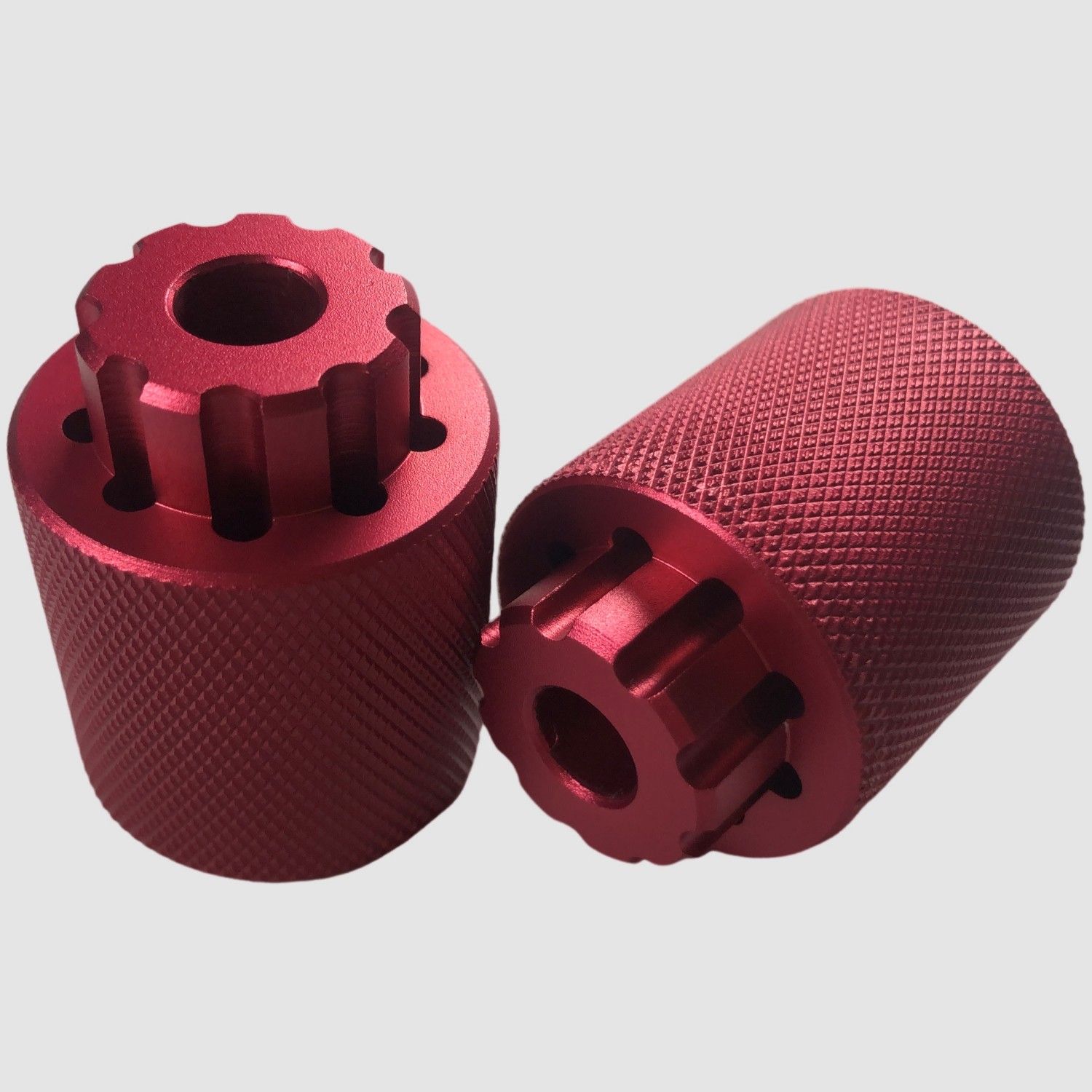

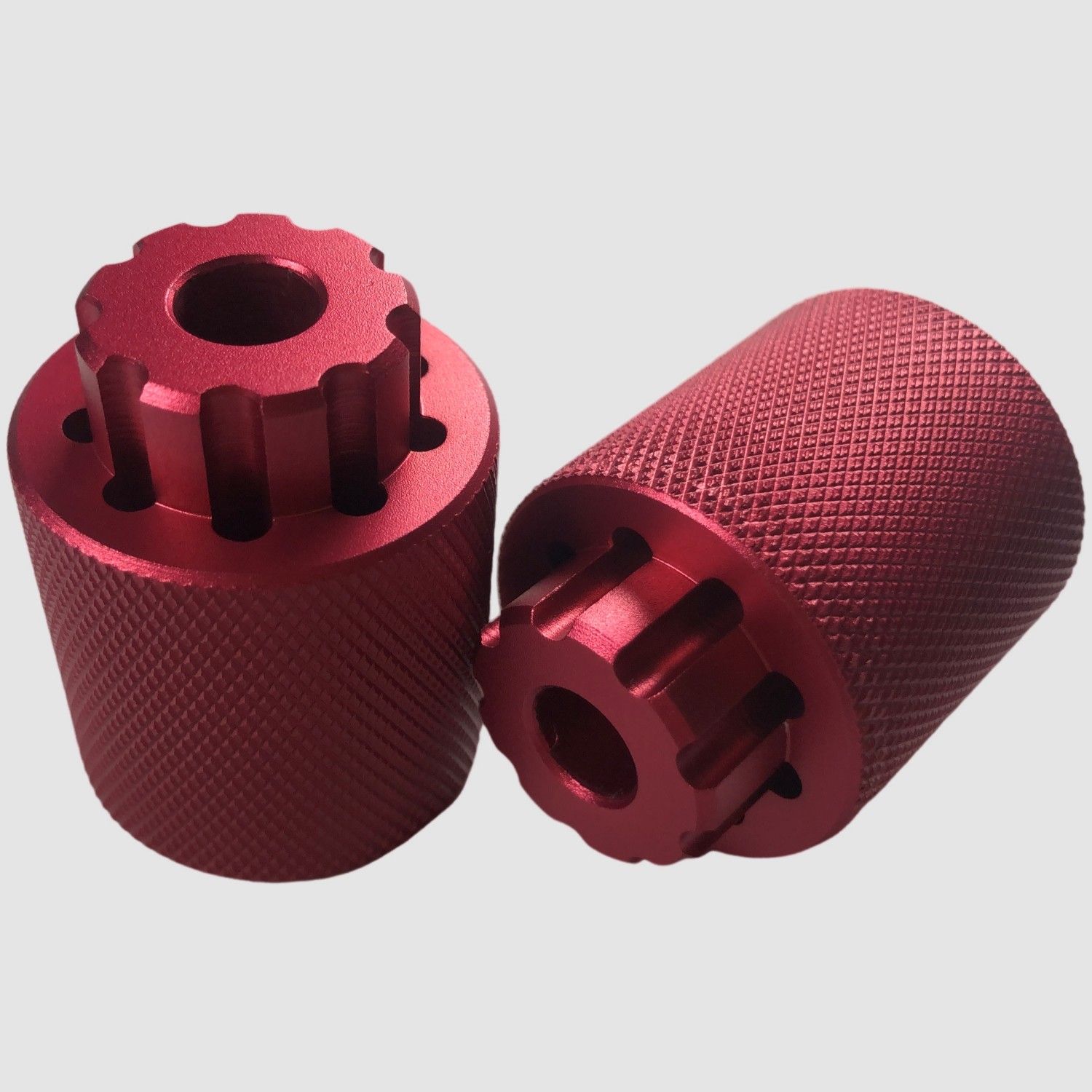

| Surface Finishes for Home Appliance Prototype |

| CNC machining leaves visible tool marks during the process of

removing portions of the block's surface to create desired shapes.

If you don't want as-machined parts, select a surface finishing for

your custom parts. At Barana Rapid, we offer several common surface

finishes that help improve functionality and aesthetics. |

| Name | Description | Materials | Color | Texture |

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance

and hardness, and protecting the metal surface. Widely used in

mechanical parts, aircraft, and automobile parts, precision

instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth,matte finish |

| Sand Blasting | Sand blasting results in parts with a smooth surface with a matte

texture. Used mainly for visual applications and can be followed by

other surface treatments. | ABS,

Aluminum,

Brass | N/A | matte |

| Powder Coating | Powder coating is a type of coating that is applied as a

free-flowing, dry powder. Unlike conventional liquid paint which is

delivered via an evaporating solvent, powder coating is typically

applied electrostatically and then cured under heat or with

ultraviolet light. | Aluminum,

Stainless Steel,

Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

| Electroplating | Electroplating can be functional, decorative or corrosion-related.

Many industries use the process, including the automotive sector,

in which chrome-plating of steel automobile parts is common. | Aluminum, steel, Stainless Steel | N/A | Smooth, Glossy finish |

| Polishing | Polishing is the process of creating a smooth and shiny surface,

either through physical rubbing of the part or by chemical

interference. The process produces a surface with significant

specular reflection, but in some materials is able to reduce

diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy |

| Brushing | Brushing is a surface treatment process in which abrasive belts are

used to draw traces on the surface of a material, usually for

aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Satin |

Quality Control and Testing: Conduct thorough quality control

checks to ensure the prototype's functionality, safety, and

adherence to specifications. Test the appliance for its intended

functions, such as heating, cooling, or other relevant features.

Evaluate its performance, energy efficiency, and user experience to

identify any necessary design refinements.

| Our First Article Inspection Process |

| When Barana Rapid receives your order requirements, we will carry

out the first article inspection service. According to our

company's regulations, Barana Rapid will provide the first article

inspection service to ensure better completion of your machining

project if the order demand reaches 3,000 US dollars or the minimum

order quantity is 300 pieces. |

| Step 1 | Step 2 | Step 3 | Step 4 |

| Barana Rapid | Offer first article inspection

We offer first article inspection services for batch production. | Draft contract

We review the project and contact customers for detailed

information. | Produce sample

We produce sample parts according to the FAI agreement and deliver

them to you. | Full-scale production

The full-scale production starts and finishes production within

lead time. |

| Client | Request inspection

You request first article inspection for a project that meets our

FAI requirements. | Sign contract

You sign the FAI agreement provided by us and agree on our Terms

and Conditions. | Receive sample

You receive and examine the parts, inform us of full-scale

production may begin. | Receive products

You receive your prototypes or production parts on the required

lead time. |