what is aluminum rapid prototyping for Aerospace industry

Aluminum rapid prototyping in the aerospace industry refers to the

use of rapid prototyping techniques and processes specifically with

aluminum materials to quickly create functional prototypes of

aerospace components or systems. This approach allows aerospace

engineers and designers to rapidly iterate and test their designs,

accelerating the development timeline and improving the efficiency

of the prototyping phase.

Aluminum is a preferred material for aerospace prototyping due to

its favorable properties, including its lightweight nature, high

strength-to-weight ratio, good machinability, and excellent thermal

conductivity. These properties make it suitable for various

aerospace applications where weight reduction, strength, and heat

management are critical factors.

The process of aluminum rapid prototyping in the aerospace industry

typically involves the following steps:

Design: Aerospace engineers and designers generate 3D CAD models of

the component or system they want to prototype. These models

capture the geometry, dimensions, and functional requirements of

the part.

Selecting a Rapid Prototyping Technique: A range of rapid

prototyping methods are available for aluminum prototyping,

encompassing additive manufacturing (like selective laser melting

or fused deposition modeling) and subtractive manufacturing (such

as CNC machining or rapid tooling). The choice of method hinges on

various factors, including the required detail level, complexity,

precision, and the resources at hand.

Prototype Production: The aluminum prototype is fabricated layer by

layer using the selected rapid prototyping technique in additive

manufacturing, or it is carved from aluminum stock material in

subtractive manufacturing. CNC machining is frequently employed for

aluminum rapid prototyping, owing to its precision and detail in

crafting parts.

Post-Processing and Finishing: After the prototype has been

created, it may undergo post-processing procedures like the removal

of support structures, sanding, polishing, or applying surface

treatments to attain the required surface finish and precision.

Testing and Evaluation: The aluminum prototype undergoes a series

of tests and evaluations to measure its performance, functionality,

and compatibility with other components or systems. These

assessments may encompass structural testing, fit and assembly

verification, functional trials, and thermal analysis.

| Our Low-volume Manufacturing Capabilities |

| Barana Rapid has over ten years of low-volume manufacturing

services and a robust supply chain. It can produce various parts

for you and provide high-quality low-volume manufacturing services.

At the same time, we have an experienced team to assist customers

in optimizing designs, selecting appropriate processes, reducing

costs, and realizing rapid mass production. |

| CNC Machining

CNC machining is used to control a wide range of complex machinery.

It is a computerized manufacturing process that uses pre-programmed

software and codes to control the movement of production equipment. | Type | Tolerance |

| Linear dimension | ±0.025mm-±0.001inch |

| Hole Diameters | ±0.025mm-±0.001inch |

| Shaft Diameters | ±0.025mm-±0.001inch |

| Part size limit | 950 * 550 * 480 mm(37.0 * 21.5 * 18.5 inch) |

| Plastic Injection Molding

Plastic injection molding is the process of melting plastic resins

(thermosetting/thermoplastic polymers) and injecting them under

pressure into a mold cavity, where they fill and solidify to form

the final product. | Standard capabilities | Description |

| Mold cavity tolerances | ±0.05 mm |

| Standard lead time | 15 business days or less |

| Part to part repeatability | ±0.1 mm |

| Production grade | 1-100,000 cycles |

| Sheet Metal Fabrication

Sheet metal fabrication converts flat sheets of steel or aluminum

into metal structures or products by cutting, stamping, folding,

and assembling. | Dimension Detail | Description |

| Edge to edge, single surface / Edge to hole, single surface / Hole

to hole, single surface | ±0.05 inch |

| Bend to edge / hole, single surface | ± 0.010 inch |

| Edge to feature, multiple surface / Over formed part, multiple

surface | ± 0.030 inch |

| Production grade | 1-100,000 cycles |

|

Vacuum Casting

Vacuum casting is a manufacturing process where the material goes

into a silicone mold with a vacuum to produce complex production

parts. | Standard capabilities | Description |

| Maximum build size | ±0.025 mm-±0.001 inch |

| Standard lead time | Up to 20 parts in 15 days or less |

| Dimensional accuracy | ±0.05 mm |

| Layer thickness | 1.5mm - 2.5mm |

|

Die Casting

Die casting is a process of manufacturing parts by pouring or

forcing molten metal into steel modes to create various kinds of

parts. | Standard capabilities | Description |

| Maximum build size | ±0.025 mm-±0.001 inch |

| Standard lead time | Up to 20 parts in 15 days or less |

| Dimensional accuracy | ±0.05 mm |

| Layer thickness | 1.5mm - 2.5mm |

|

Aluminum Extrusion

Aluminum extrusion facilitates the manufacture of complex parts

through the process of plastic deformation. Material is forced

through a mold or orifice to achieve the desired shape. | Standard capabilities | Description |

| Press sizes | 450T - 3000T |

| Standard lead time | 2 weeks for small molds,

4 weeks for larger molds |

| Minimum order volume | 0.5 ton aluminum for smaller machines, 1.0 ton of 6063 aluminum for

larger machines. |

| Post-processing | Full service CNC cutting, threading, slotting, face milling, etc. |

|

3D Printing

3D printing is a manufacturing process in which a three-dimensional

part or object is created from a digital 3D or CAD model. | Standard capabilities | Description |

| Min. wall thickness | 1.0 mm |

| Layer height | 50 – 300 μm |

| Max. build size | 250 * 250 * 250 mm (SLA), 420 * 500 * 420 mm (SLS), 500 * 500 * 500

mm (FDM) |

| Tolerance | ± 0.5% with a lower limit of ± 0.5 mm (± 0.020″) |

Iterative Design Optimization: Based on the test results and

evaluation feedback, necessary design modifications can be made to

improve the prototype. The rapid prototyping process allows for

quick iterations, enabling engineers to refine and optimize the

design until it meets the required specifications and performance

criteria.

| Our Vacuum Casting Tolerances |

| Barana Rapid offers a range of vacuum casting tolerances to meet

your complex custom requirements. Depending on the master model and

part geometry, we can achieve dimensional tolerances between 0.2 –

0.4 m. Below are the technical specifications for our custom vacuum

casting services. |

| Type | Information |

| Accuracy | Highest precision to reach ±0.05 mm |

| Max Part Size | +/- 0.025 mm

+/- 0.001 inch |

| Minimum wall thickness | 1.5mm~2.5mm |

| Quantities | 20-25 copies per mold |

| Color & Finishing | Color and texture can be customized |

| Typical Lead Time | Up to 20 parts in 15 days or less |

Aluminum rapid prototyping in the aerospace industry offers several

benefits, including reduced development time, cost savings,

improved design validation, accelerated design iterations, and the

ability to test and validate concepts before committing to

full-scale production. It allows aerospace engineers to quickly

visualize, evaluate, and refine their designs, ultimately leading

to the development of high-quality aerospace components or systems.

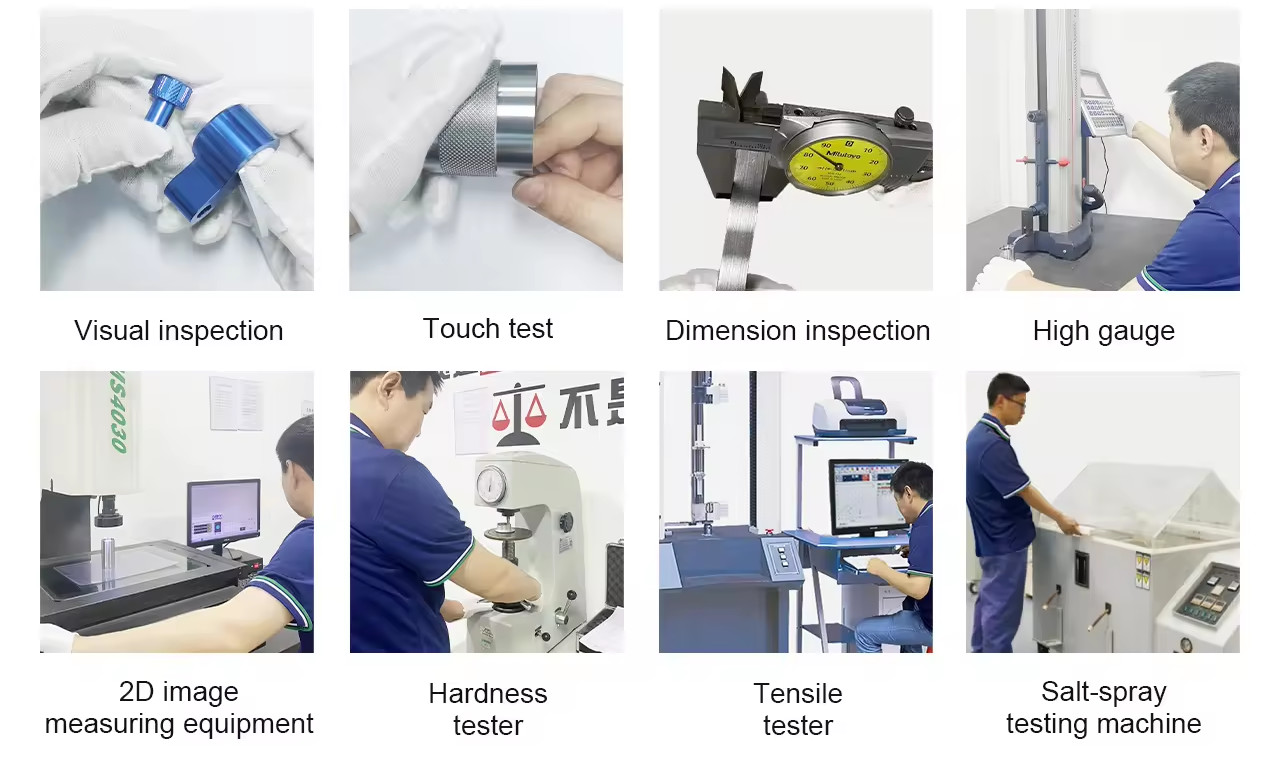

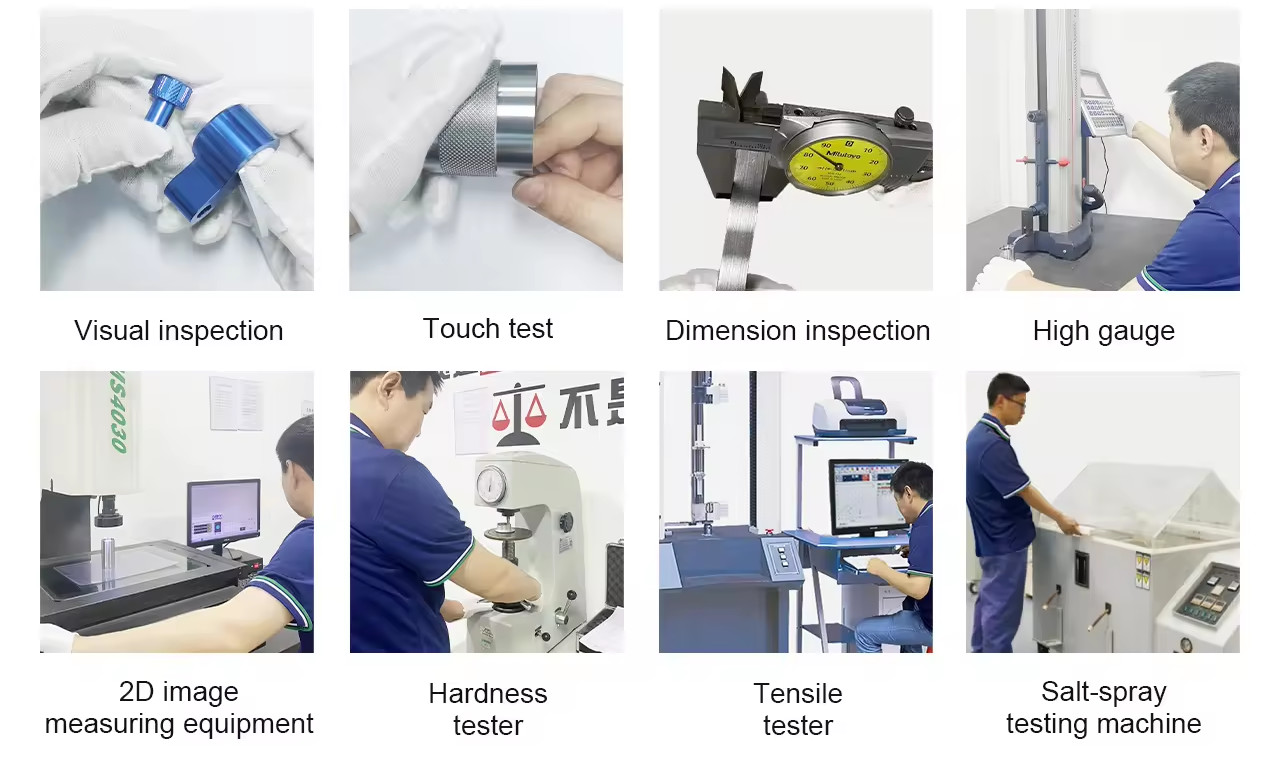

What Separates Barana Rapid’s Inspection Processes from the Rest?

Careful measurement, inspection and testing are necessary to ensure

the conformance of your parts. We perform multiple inspections at

every step of the product development journey, from incoming

material verification to final 3D scanning. You will receive

complete digital files and Certificates of Compliance so you can

meet your own regulatory and performance goals.

An International Team with Unparalleled Experience

Quality inspection relies not only upon using advanced digital

equipment but also having highly trained personnel with years of

experience. As parts become more complex and tolerances more

demanding for advanced applications, precision measurements

conducted by professionals are the only way to ensure perfection.

Inspections and Review for Every Stage of Production

To ensure quality from start to finish, Barana Rapid provides the

following inspection and review services:

Extensive incoming materials verification

Design for manufacturing reviews for all quotes provided

Contract reviews upon receipt of POs

First article and in-process inspections

Final inspections and testing with reports and certifications as

required