Introduction of Sheet Metal Fabrication

Sheet metal fabrication is a comprehensive manufacturing process

that shapes and forms sheet metal into specific parts and

components. This process includes a range of techniques and

procedures for cutting, bending, punching, welding, and assembling

sheet metal to produce the final product. It is widely utilized in

sectors like automotive, aerospace, construction, and electronics,

among others. The following are some principal elements and

procedures in sheet metal fabrication:

Material Selection: Sheet metal can be made from a variety of

materials, including steel, aluminum, stainless steel, copper,

brass, and more. The choice of material depends on factors such as

desired strength, corrosion resistance, weight, cost, and specific

application requirements.

Cutting and Shearing: Sheet metal is typically cut into the desired

shape and size using various methods. Common cutting techniques

include laser cutting, plasma cutting, waterjet cutting, and

mechanical shearing. These methods provide precise and clean cuts,

ensuring accurate dimensions for subsequent forming processes.

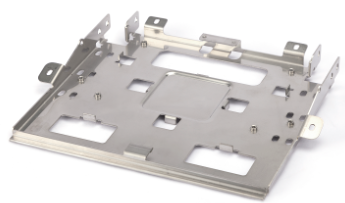

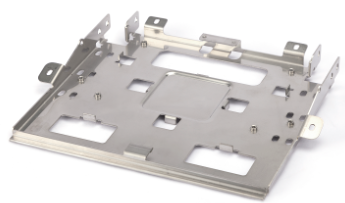

Forming and Bending: In sheet metal fabrication, forming and

bending are essential for transforming flat sheets into

three-dimensional shapes. Press brakes are frequently utilized to

manipulate the metal, facilitating the formation of angles, curves,

flanges, and various structural elements. Additionally, roll

forming and stamping may be used for certain specialized tasks.

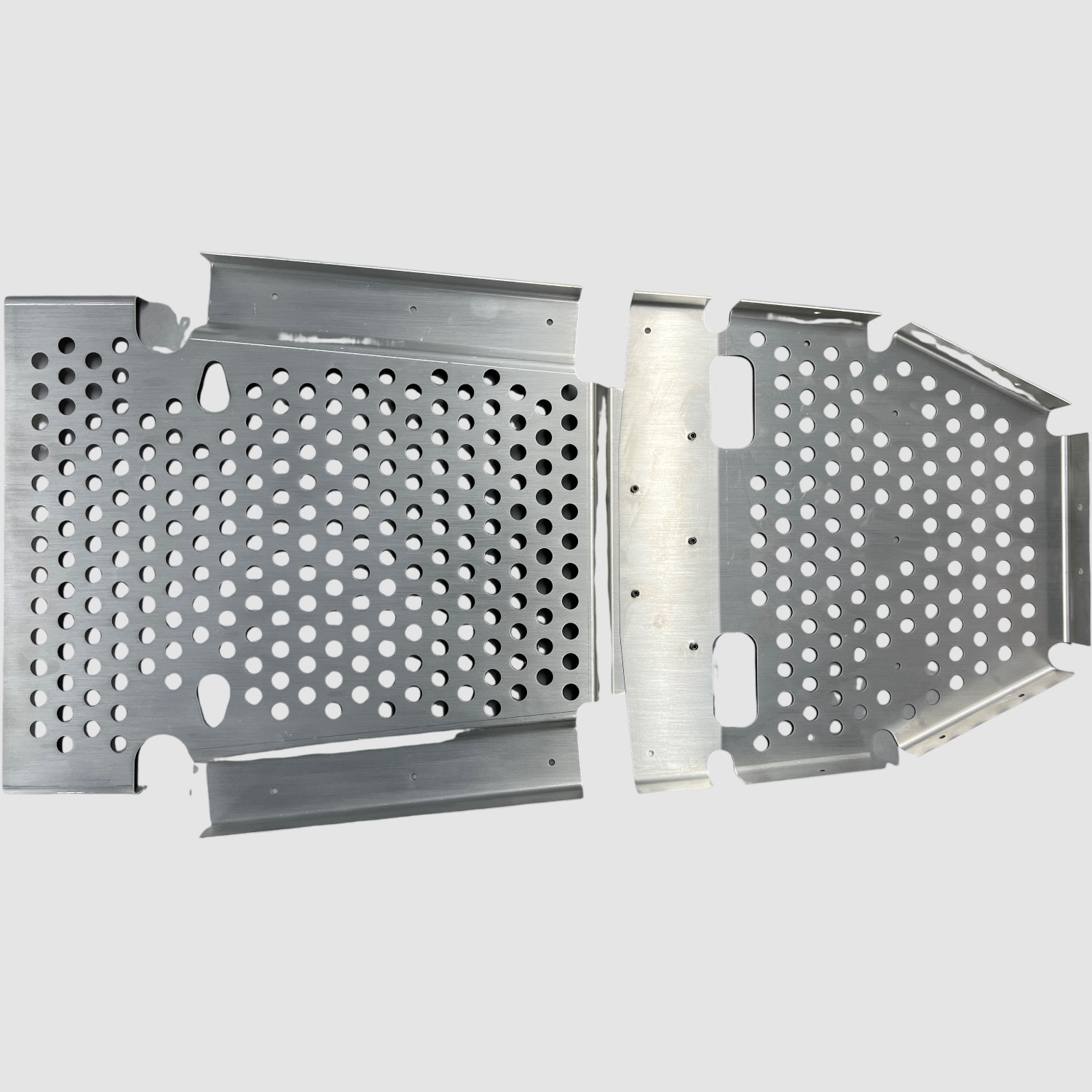

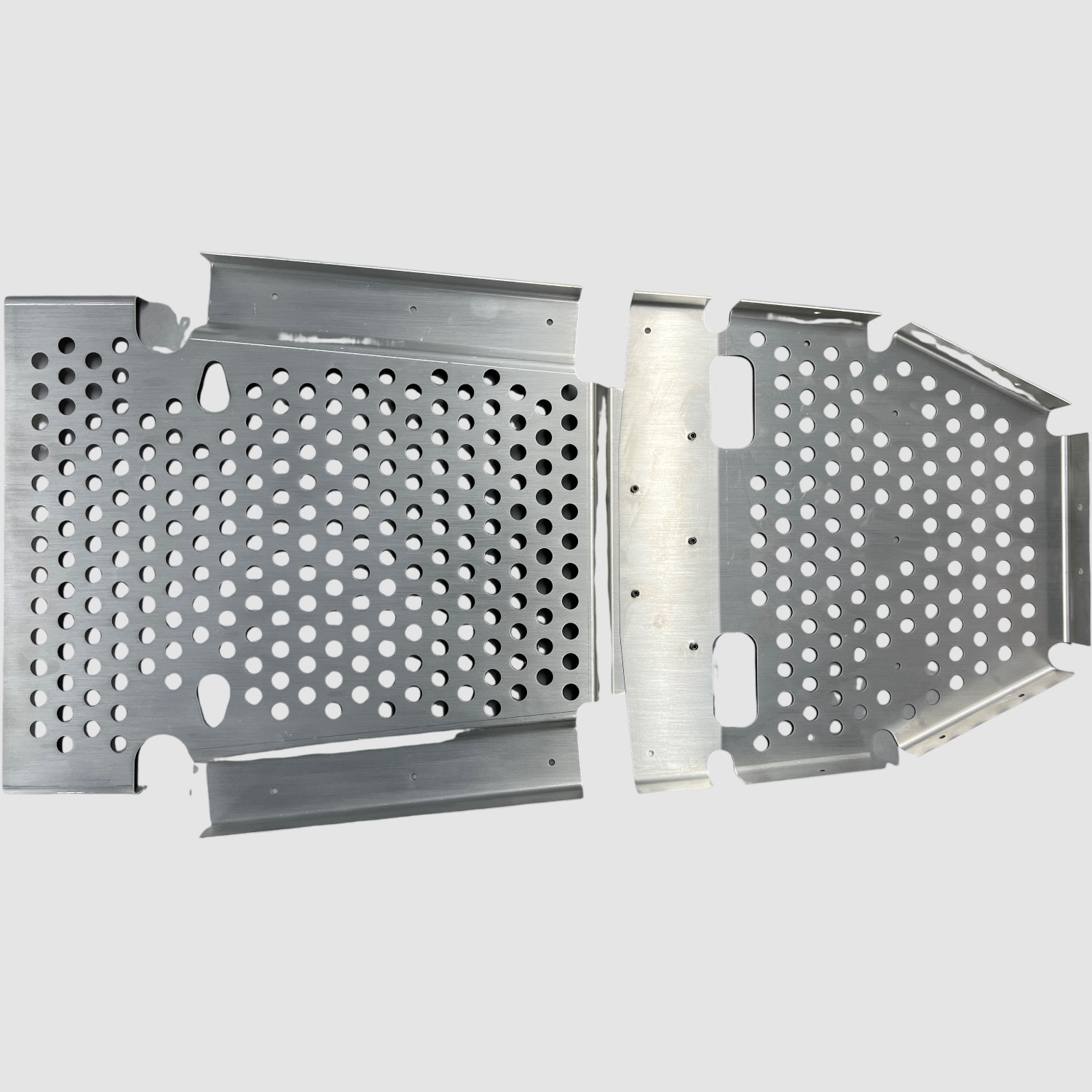

Punching and Perforating: Punching is the process of creating

holes, slots, or various patterns in sheet metal. This is done

using punching machines equipped with specialized tooling to

penetrate the material, allowing for the addition of fasteners,

ventilation, or decorative elements. Perforating is a related

technique that produces a pattern of evenly spaced holes in sheet

metal, serving specific functional or aesthetic objectives.

Welding and Joining: Welding is utilized to fuse multiple sheet

metal pieces into a larger assembly or structure. Popular welding

methods in sheet metal fabrication encompass MIG (Metal Inert Gas)

welding, TIG (Tungsten Inert Gas) welding, and spot welding. These

techniques provide robust and lasting joints between metal

components.

| Sheet Metal Fabrication Standards |

| To ensure part maneuverability and precision of fabricated

prototypes and parts, our custom sheet metal fabrication services

are in compliance with the ISO 2768-m. |

| Dimension Detail | Metric Units | Imperial Units |

| Edge to edge, single surface | ±0.127 mm | ± 0.005 in. |

| Edge to hole, single surface | ±0.127 mm | ± 0.005 in. |

| Hole to hole, single surface | ±0.127 mm | ± 0.005 in. |

| Bend to edge / hole, single surface | ±0.254 mm | ± 0.010 in. |

| Edge to feature, multiple surface | ±0.762 mm | ± 0.010 in. |

| Over formed part, multiple surface | ±0.762 mm | ± 0.030 in. |

| Bend angle | ± 1° | |

| By default, sharp edges will be broken and deburred. For any

critical edges that must be left sharp, please note and specify

them in your drawing. |

Finishing and Surface Treatment: After the fabrication processes,

sheet metal parts may undergo finishing treatments to improve their

appearance and enhance their performance. Surface treatments can

include cleaning, deburring, grinding, polishing, painting, powder

coating, or applying protective coatings to increase resistance to

corrosion or wear.

Assembly and Integration: Sheet metal parts are frequently

assembled and integrated with other components to form a complete

product or system. This process can include fastening using screws,

rivets, or adhesives, and adding extra elements like hinges,

handles, brackets, or electrical connectors.

Sheet metal fabrication offers several advantages, including high

strength-to-weight ratio, versatility in design, cost-effectiveness

for large-scale production, and suitability for both functional and

decorative applications. It enables the creation of a wide range of

products, from simple brackets and enclosures to complex structural

components and machinery.

That sounds like a comprehensive range of materials for your sheet

metal fabrication services. Each material you mentioned has its own

unique properties and advantages. Here's a brief overview of the

materials you listed:

| Sheet Metal Fabrication Materials |

| Whatever the application and requirements of your sheet metal

fabrication part, trust Barana Rapid to find the right sheet metal

fabrication material. Some popular materials available for custom

metal fabrication are outlined below. |

| Aluminum

Commercially, aluminum is the most sought-after material for sheet

metal manufacturing. Its popularity is due to its adaptive

qualities and its high thermal conductivity and low resistance

rates. Compared to steel—another common sheet metal

material—aluminum is more cost-effective and has a higher rate of

production. The material also generates the least amount of waste

and can easily be reused. | Features | Info |

| Subtypes | 6061-T6, 7075-T6, 7050, 2024, 5052, 6063, etc |

| Process | CNC machining, injection molding, sheet metal fabrication |

| Tolerance | With drawing: as low as ± 0.005 mm No drawing: ISO 2768 medium |

| Applications | Light & economic, used from prototyping to production |

| Finishing Options | Alodine, Anodizing Types 2, 3, 3 + PTFE, ENP, Media Blasting,

Nickel Plating, Powder Coating, Tumble Polishing. |

| Copper

Copper is a broadly used sheet metal fabrication material in many

industries as it offers good malleability and ductility. Copper is

also well suited for sheet metal fabrication because of its

excellent heat conduction properties and electrical conductivity. | Features | Info |

| Subtypes | 101,110 |

| Process | CNC machining, sheet metal fabrication |

| Tolerance | ISO 2768 |

| Applications | Bus bars, gaskets, wire connectors, and other electrical

applications |

| Finishing Options | Available as-machined,media blasted, or hand-polished |

| Brass

Brass has desirable properties for a number of applications. It is

low friction, has excellent electrical conductivity and has a

golden (brass) appearance. | Features | Info |

| Subtypes | 101,110 |

| Process | CNC machining, sheet metal fabrication |

| Tolerance | ISO 2768 |

| Applications | Bus bars, gaskets, wire connectors, and other electrical

applications |

| Finishing Options | Available as-machined,media blasted, or hand-polished |

| Steel

Steel offers a number of beneficial properties for industrial

applications, including rigidity, longevity, heat resistance and

corrosion resistance. Steel sheet metal is ideal for producing

complex designs and parts that require extreme precision. Steel is

also cost-efficient to work with and has excellent polishing

properties. | Features | Info |

| Subtypes | 4140, 4130, A514, 4340 |

| Process | CNC machining, sheet metal fabrication |

| Tolerance | With drawing: as low as ±0.005 mm No drawing: ISO 2768 medium |

| Applications | Fixtures and mounting plates; draft shafts, axles, torsion bars |

| Finishing Options | Black Oxide, ENP, Electropolishing, Media Blasting, Nickel Plating,

Powder Coating, Tumble Polishing, Zinc Plating |

| Stainless Steel

Stainless steel is the low carbon steel that contains a minimum of

10% chromium by weight. The material properties associated with

stainless steel have made it a popular metal within a broad range

of industries, including construction, automotive, aerospace and

more. Within these industries, Stainless steel is versatile and is

an effective choice for many applications. | Features | Info |

| Subtypes | 303, 304L, 316L, 410, 416, 440C, etc |

| Process | CNC machining, sheet metal fabrication |

| Tolerance | With drawing: as low as ±0.005 mm No drawing: ISO 2768 medium |

| Applications | Industrial applications, fittings, fasteners, cookware, medical

devices |

| Finishing Options | Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating,

Passivation, Powder Coating, Tumble Polishing, Zinc Plating |