Introduction of Sheet Metal Fabrication

Sheet metal fabrication is a comprehensive manufacturing process

that shapes and forms sheet metal into specific parts and

components. This process includes a range of techniques and

procedures for cutting, bending, punching, welding, and assembling

sheet metal to produce the final product. It is widely utilized in

sectors like automotive, aerospace, construction, and electronics,

among others. The following are some principal elements and

procedures in sheet metal fabrication:

Material Selection: Sheet metal can be made from a variety of

materials, including steel, aluminum, stainless steel, copper,

brass, and more. The choice of material depends on factors such as

desired strength, corrosion resistance, weight, cost, and specific

application requirements.

Cutting and Shearing: Sheet metal is typically cut into the desired

shape and size using various methods. Common cutting techniques

include laser cutting, plasma cutting, waterjet cutting, and

mechanical shearing. These methods provide precise and clean cuts,

ensuring accurate dimensions for subsequent forming processes.

Forming and Bending: Forming and bending are crucial processes in

sheet metal fabrication to create three-dimensional shapes from

flat sheets. Press brakes are commonly used to bend and shape the

metal, allowing for the creation of angles, curves, flanges, and

other structural features. Roll forming and stamping processes may

also be employed for specific applications.

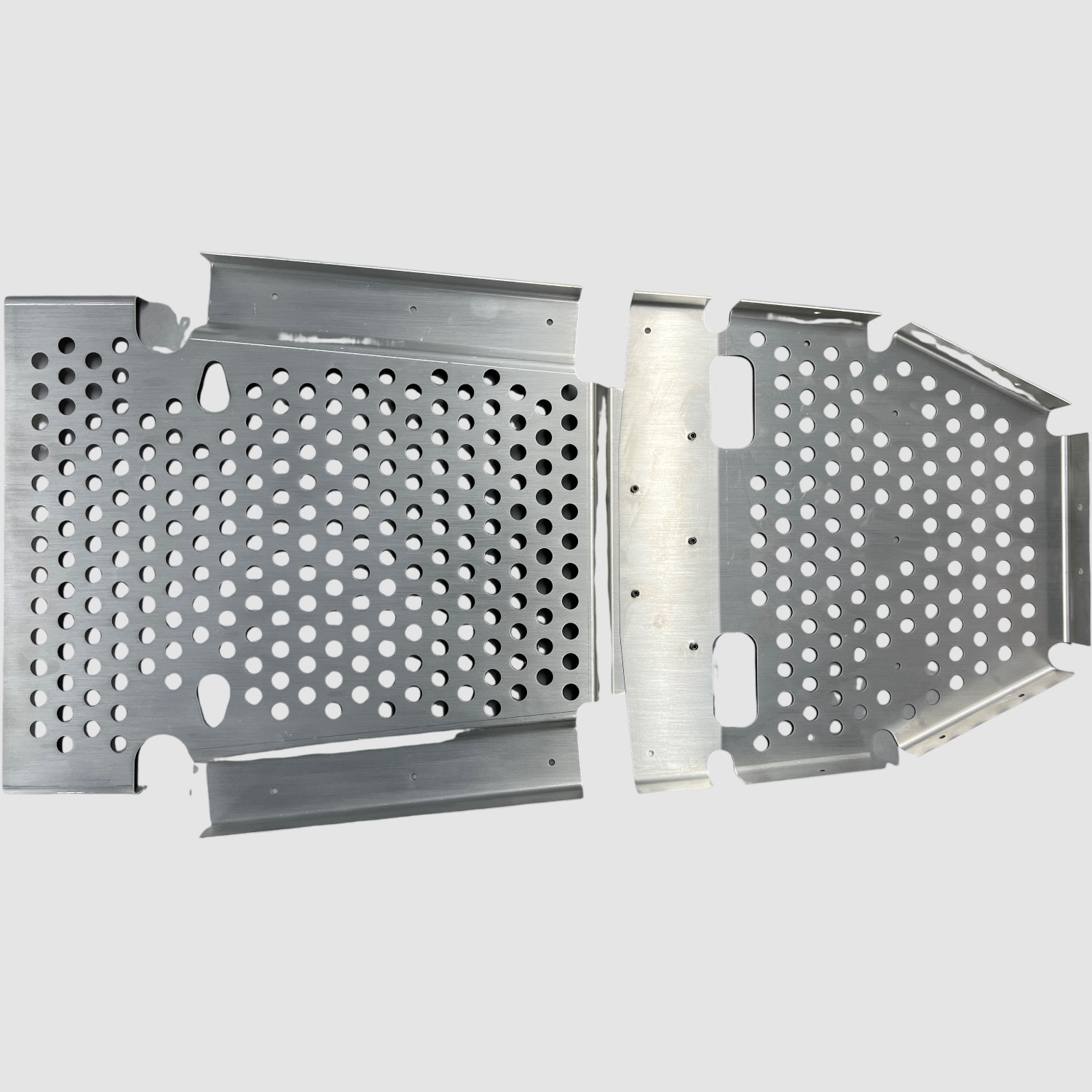

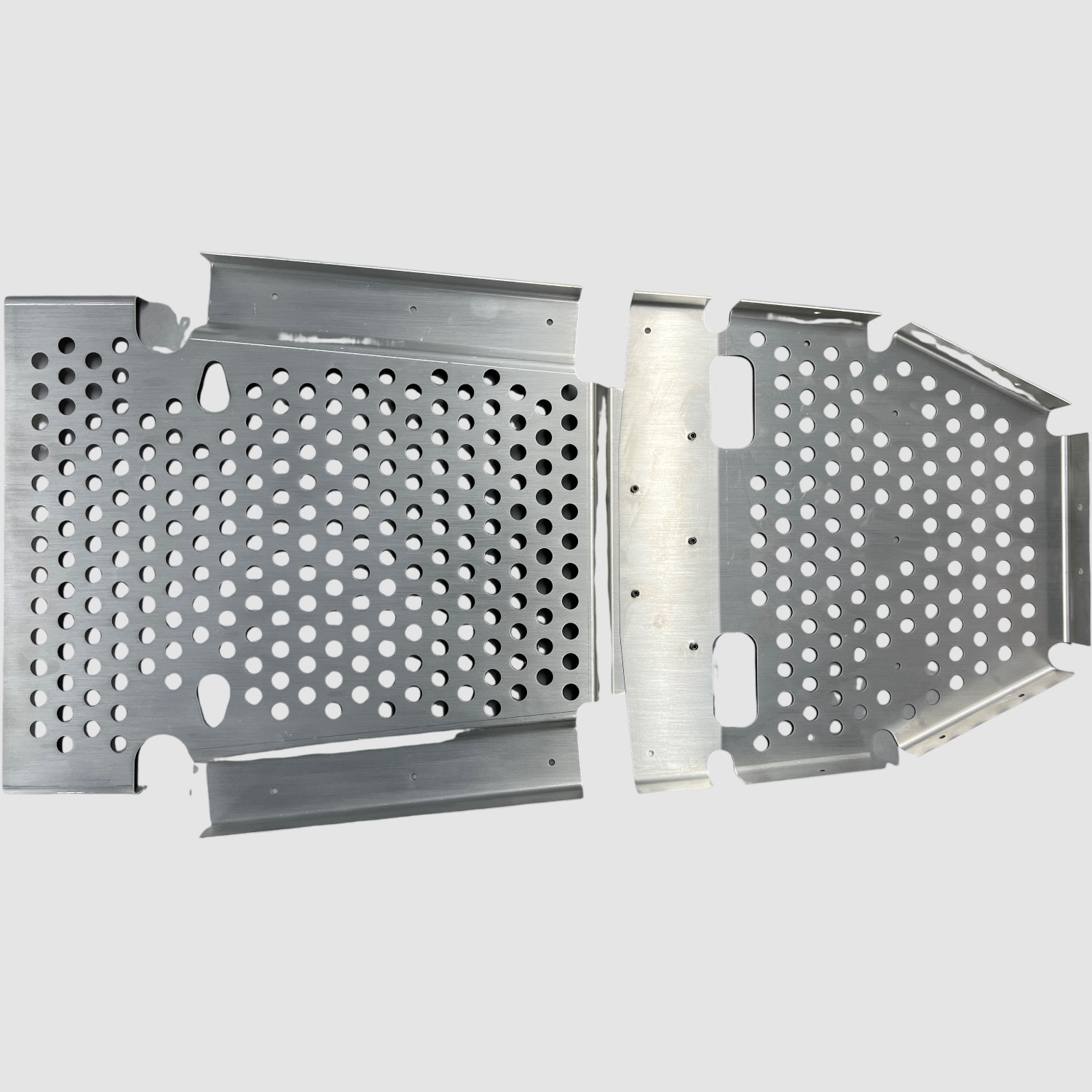

Punching and Perforating: Punching involves creating holes, slots,

or other patterns in the sheet metal. Punching machines use

specialized tooling to cut through the material, enabling the

incorporation of fasteners, ventilation, or aesthetic features.

Perforating is a similar process that creates a pattern of

regularly spaced holes in the sheet metal for specific functional

or decorative purposes.

Welding and Joining: Welding is employed to join multiple sheet

metal components together to create a larger assembly or structure.

Common welding techniques used in sheet metal fabrication include

MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding,

and spot welding. These methods ensure strong and durable

connections between the metal parts.

| Sheet Metal Fabrication Standards |

| To ensure part maneuverability and precision of fabricated

prototypes and parts, our custom sheet metal fabrication services

are in compliance with the ISO 2768-m. |

| Dimension Detail | Metric Units | Imperial Units |

| Edge to edge, single surface | ±0.127 mm | ± 0.005 in. |

| Edge to hole, single surface | ±0.127 mm | ± 0.005 in. |

| Hole to hole, single surface | ±0.127 mm | ± 0.005 in. |

| Bend to edge / hole, single surface | ±0.254 mm | ± 0.010 in. |

| Edge to feature, multiple surface | ±0.762 mm | ± 0.010 in. |

| Over formed part, multiple surface | ±0.762 mm | ± 0.030 in. |

| Bend angle | ± 1° | |

| By default, sharp edges will be broken and deburred. For any

critical edges that must be left sharp, please note and specify

them in your drawing. |

Finishing and Surface Treatment: After the fabrication processes,

sheet metal parts may undergo finishing treatments to improve their

appearance and enhance their performance. Surface treatments can

include cleaning, deburring, grinding, polishing, painting, powder

coating, or applying protective coatings to increase resistance to

corrosion or wear.

Assembly and Integration: Sheet metal components are often

assembled and integrated with other parts to create a final product

or system. This may involve fastening with screws, rivets, or

adhesives, as well as incorporating additional components such as

hinges, handles, brackets, or electrical connectors.

Sheet metal fabrication offers several advantages, including high

strength-to-weight ratio, versatility in design, cost-effectiveness

for large-scale production, and suitability for both functional and

decorative applications. It enables the creation of a wide range of

products, from simple brackets and enclosures to complex structural

components and machinery.